Self Steer vs Passive Steer Axles

Self Steer Axle

Benefits

- Better turning circle than fixed axles in forwards travel

- Reduced tyre wear than fixed axles

- Simple to maintain

Limitations

- Can Not be reversed

- Needs to be driven forwards to lock/lift for reverse travel

- 13-15 degree steer angle only

Passive steer system

Benefits

- Better turning circle than fixed axles in forwards travel (Same as self Tracking)

- Reduced tyre wear than fixed axles (same as self tracking)

- Can be reversed with some tyre scrub

Limitations

- 13-15 degree steer angle only

- More Expensive than self tracking

- More complicated control system

‘Passive’ Steer is actually Self Steer/tracking Axle, something that does not require any power.

Self Steer Axles

Self Steer/tracking axles use the lateral forces generated in a turn (through Kingpin geometry) to correct this tendency and steer the wheels slightly to the inside of the corner. This improves the stability of the vehicle through the turn.

Self Steer Axle

This self steer axle requires locking and or lifting when reversing the combination otherwise the wheels would steer in the wrong direction for the manoeuvre. This can create issues if trying to reverse turn in a small space as the combination needs to be driven forwards first to centralise for locking.

Passive Steer Axle

Passive steer can be described as steering one axle by either cross linkage, or bracing, or hydraulic fluid transfer displacement when either another axle steers or the towing vehicle & trailer articulate.

We would be more familiar with hydraulic ram between towing vehicle (Agri Tractor) and Trailer (Agri Trailer) which when the angle changes between towing vehicle and trailer the ram displaces fluid into another ram attached to the rear steer axle. Closed system, no power required fluid displacement causes rear axle to steer.

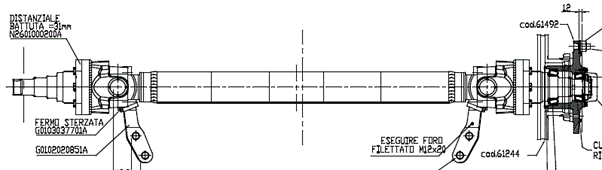

The axle is generally self steer axle with two steer rams attached, ie the axle steering pin (King pin) is forward of the axle lateral centre line so without any ram fitted the wheels would self steer or caster in the direction that the turning of the trailer would dictate.

Max steer angle around 13-14 degrees which is ok for forwards travel, not so good in reverse as this is the ‘Rear’ axle of the combination and thus the lead axle in reverse. Because of this there is likely to be some tyre scrub in reverse.

Self tracking axle with ‘passive steer’ rams.

This self steer axle requires locking and or lifting when reversing the combination otherwise the wheels would steer in the wrong direction for the manoeuvre. This can create issues if trying to reverse turn in a small space as the combination needs to be driven forwards first to centralise for locking.

Command Steer Axles

Command steer is a powered system where a controlling sensor / linkage senses the steer angle between the towing vehicle and the trailer or steering input from driver and remotely demands the correct pressure/volume in the steer rams at the rear to steer the axle to the desired amount. The axle steering pins (King pins) are directly on the axle lateral centre line. When reversing this axle is the leading axle of the combination and thus with the wheels steered correctly to the demand this aids reverse steering. Max steer angle 30-40 degrees much better for reversing. Many commercial specialist low loaders will have at least one or 2 full rear steers along with the ‘Longer Semi Trailers’

Active Steer

Would use a command steer axle with computer to control the steering angle of the axle.